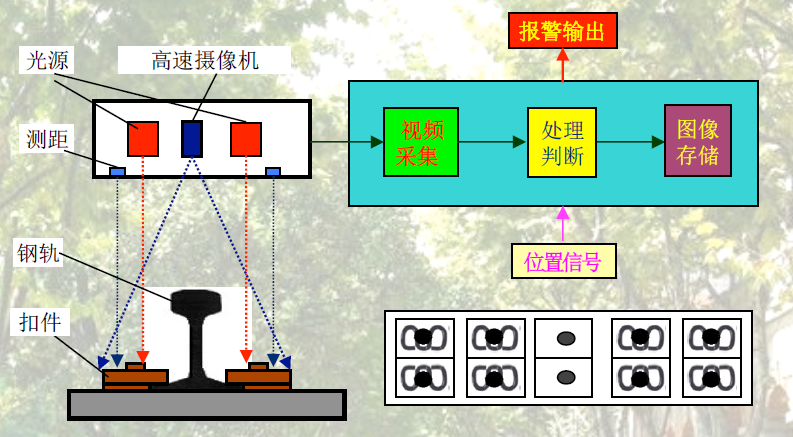

It adopts the pulse lasers to detect the location of fastening. Then the system triggers the image acquisition model.

It uses the LED as the area light source. With the assistance of high-speed industry camera, the system can acquire the situation information in the fastening area.

After continuing photo acquisition to the railway fastening, the system sends the information in high-speed parallel transfer mode. Then it processes the data to get the result of detection.

It would use the off-line estimating methods to confirm the precision.

Characteristic:

Synchronous position: It can adapt the changes in velocity, meet the high-speed requirements, and avoid the repeating measurement.

Visual inspection: It has advantages of widely using, high degree of intelligence, and easily solving the vibration, moving and rocking problems.

Real-time acquisition: It ensures the real-time of fastening detection and, meets the precise and reliability requirements of the system.

Asynchronous processing: The parallel processing reduces the processing time and meets the high-speed requirement.