This measurement instrument adopts the principle of differential laser triangulation technique. By scanning two laser displacement sensors in horizontal directions, high accurate thickness and convexity measurements of the cold/hot rolled steel in width are performed. Both online and offline measurements are allowed. The measurement is of high accuracy and repeatability. It can be used to measure different materials and steels of different surface properties. It has good anti-interference ability and is suitable for field inspection near the production line.

Measurement System 测量系统

Key features:

· Non-contact measurement: laser triangulation principle;

· Point measurement of thickness: diameter of the laser spot is only tens of micro meters;

· High accuracy: the measurement accuracy can reach 3μm;

· Fast measurement speed: sampling frequency is 50KHz;

· Automatic measurement: one key operation;

· High adaptability: can measure different material surfaces;

· Anti-interference: differential measurement can eliminate interferences such as vibration;

· Simple and initiative: can be operated by computer or be operated manually. Images and data are displayed.

· Safe operation: visible light is used; harmless to human and non-pollution to the environment.

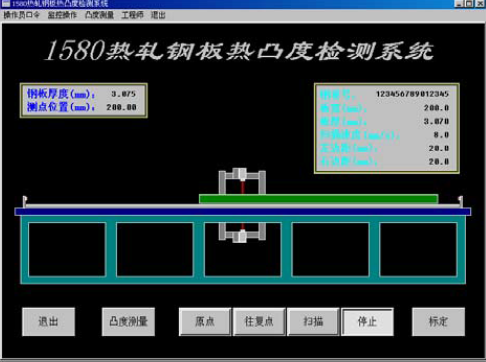

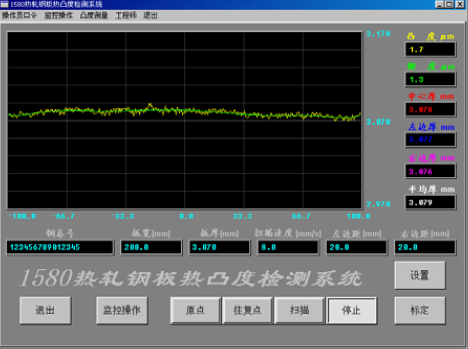

Display Panel 显示画面

|